The data center uses a 110KV substation as the main incoming line. It is planned to cover an area of over 30,000 square meters. The construction area of the first phase will reach 15,000 square meters, and the total design capacity will reach 200,000 KVA. The computer room adopts the international T3+/domestic A-level standard construction (2N), which can accommodate 15,000 cabinets. The first phase of the project includes 2 high-voltage power transformation and distribution rooms, 3 low-voltage power transformation and distribution rooms, 5 battery rooms, and 5 conventional Data room and 2 carrier data rooms.

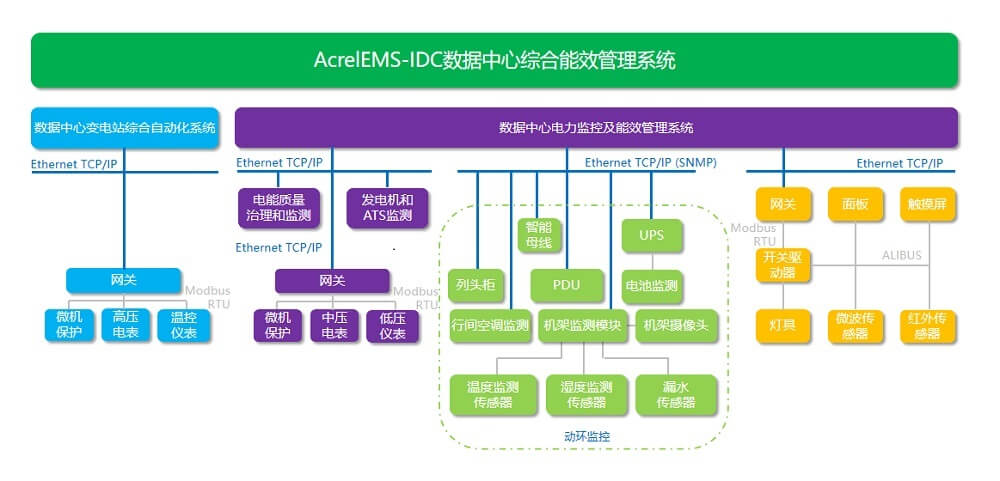

In the monitoring requirements of the data center computer room, our company has formulated a complete set of solutions according to the project requirements, including monitoring the power distribution monitoring of the power parameters of each incoming and outgoing circuit of the high and low voltage power distribution room, monitoring the head cabinet, UPS , battery, air conditioner status and various parameters and other equipment monitoring, monitoring the temperature and humidity of the computer room, water immersion, hydrogen in the battery room and other environmental monitoring, monitoring IT, air conditioning, power, lighting and other sub-item energy consumption analysis, recording data center remote signaling alarm, Event records such as telemetry alarms and operation and maintenance management such as helping on-site operation and maintenance personnel to release and confirm inspection tasks. Through the joint efforts of our staff and various staff, we have met customer needs, improved user experience, and achieved project goals.

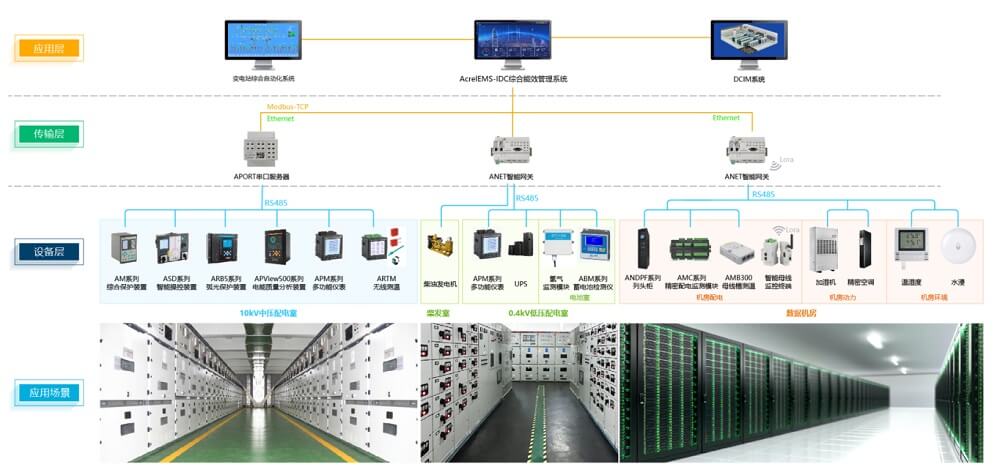

The first phase of the data center project involves two 110KV main transformers, eight low-voltage transformers with a total capacity of 20,000 KVA, two high-voltage transformer and distribution rooms, and four low-voltage transformer and distribution rooms.

The low-voltage power distribution room is equipped with UPS equipment to ensure power supply. Each power distribution room is equipped with ANet-2E4SM modular gateway equipment. Involving 7 computer rooms. Two of them are operating computer rooms. The remaining 5 conventional data computer rooms have a total of 70 top cabinets and 33 air conditioners. The data of top cabinets and air conditioners are forwarded to the gateway device through Ethernet (Modbus-TCP), and the gateway device collects and uploads the comprehensive energy efficiency of AcrelEMS-IDC management system. A total of 16 ANet-2E4SM modular gateway devices are used.

Monitor the total energy consumption of the data center, IT energy consumption, air conditioning energy consumption, power consumption, and calculate the PUE value

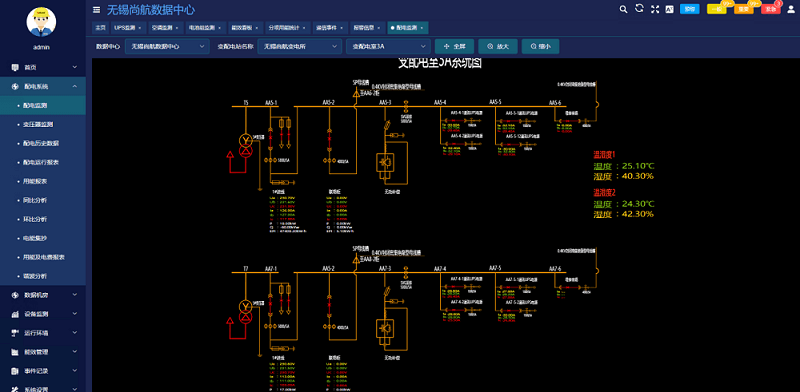

According to the structure of each power distribution room, draw a single line diagrams (SLD)

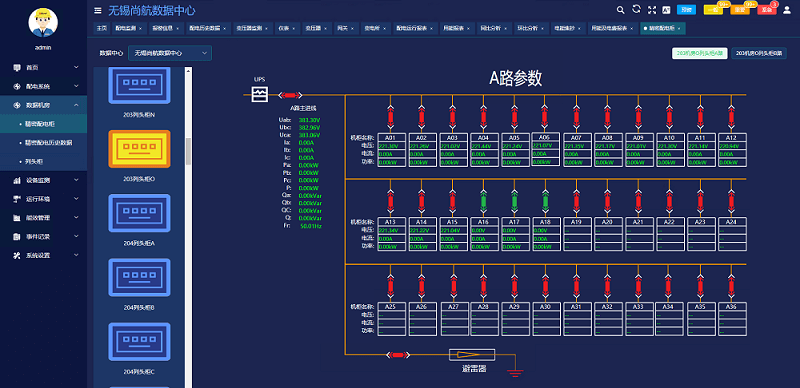

Monitor the parameters of each head cabinet and its branches in the computer room

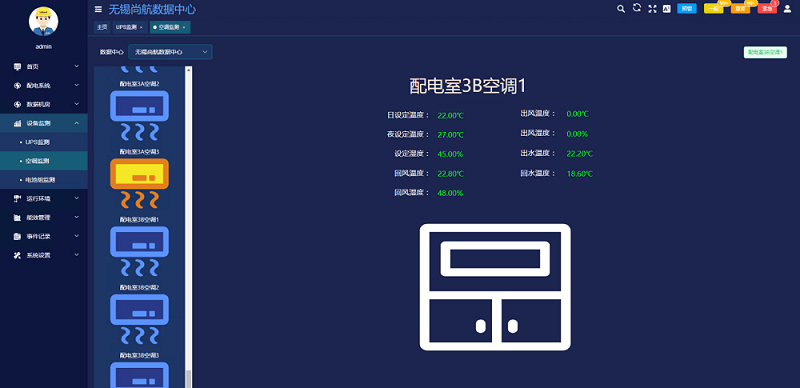

Monitor the return air temperature and humidity of the air conditioner, and the temperature of the return water

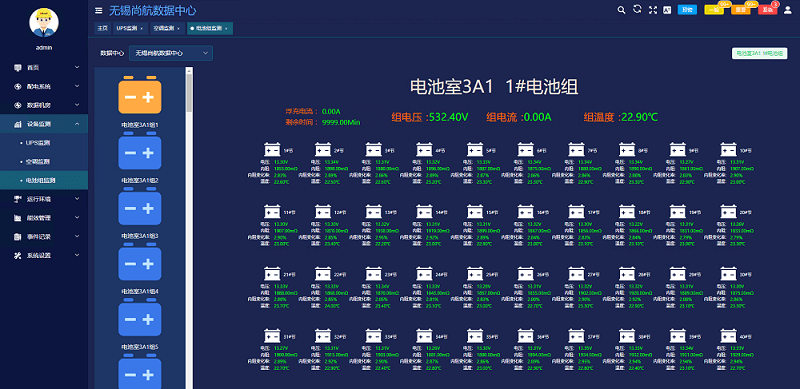

Monitor battery pack voltage, current, float current, pack temperature. Single battery voltage, internal resistance, temperature

The system is divided into four levels of alarms, covering all major equipment and power distribution circuits in the data center

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]