December 14, 2022

Modern diagnosis and treatment are inseparable from various advanced medical equipment, and all kinds of equipment are inseparable from the power supply.

Many operations often last for several hours, and the consequences of a sudden power failure during the operation are unimaginable; at the same time, many medical devices directly contact or penetrate into the internal organs of the human body. At this time, a small leakage current will threaten the life of the patient.

Therefore, for the continuity and safety of the power supply of the hospital power distribution system, the relevant national standards have made clear requirements that important equipment in medical class 2 places must be powered by the IT system, and the IT system needs to be equipped with insulation monitoring devices.

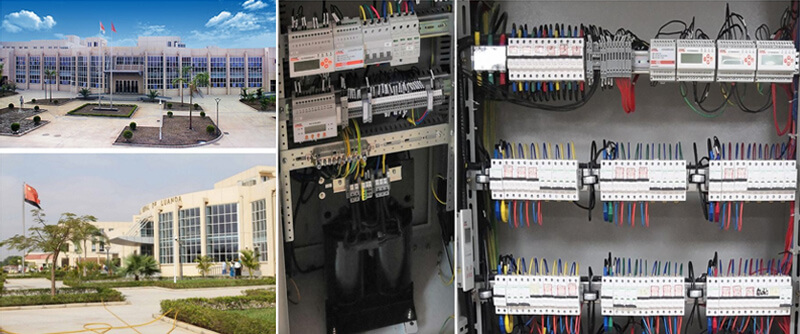

This article introduces the application of Acrel Medical IT system in Luanda General Hospital, Angola.

Angola Luanda General Hospital is a Chinese-aided Angola Luanda General Hospital renovation and expansion project undertaken by China Railway Fourth Bureau

The project used 8 sets of ACREL medical IT system products.

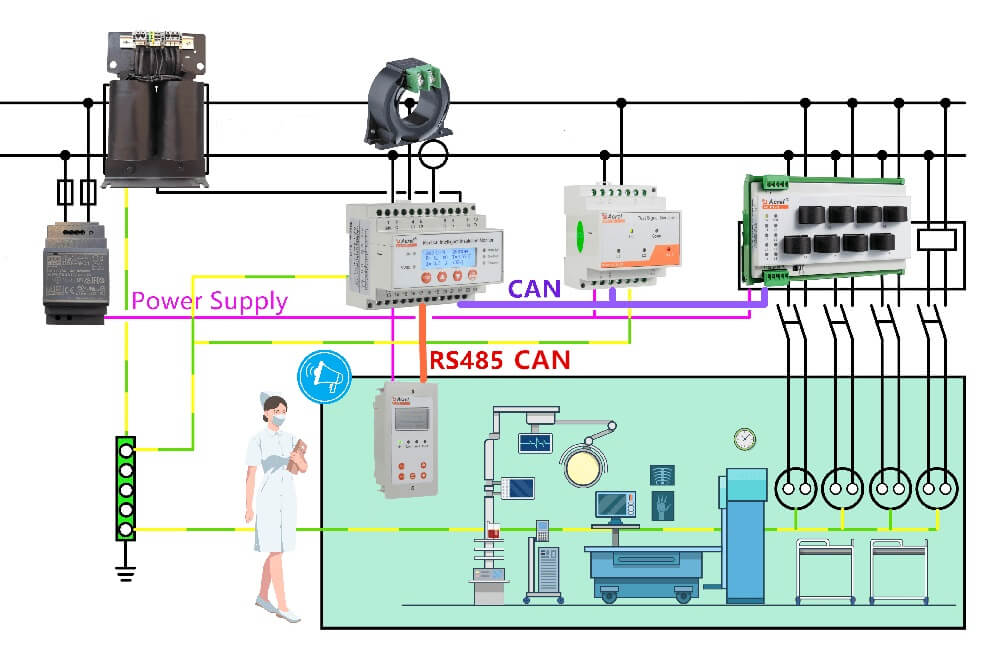

Mainly include: AITR series isolation transformers, AIM-M series insulation monitors, AID series alarm displays, and AKH-0.66P26 current transformers.

Composition of the medical isolated power supply system

The isolated power supply provides isolated and safe power for important places in the hospital through the isolation transformer, and the transformation ratio is 1:1. The number of turns of the primary coil of this transformer is equal to the number of turns of the secondary coil. At the same time, the primary coil and the secondary coil are highly insulated, and an electrostatic shielding screen is set to minimize the electromagnetic interference between the two windings.

The insulation monitor is used to monitor the insulation status of the IT system to the ground. When the insulation fault occurs in the system, it can send an alarm signal in time to remind the staff to deal with it according to the actual situation. At the same time, it can also monitor the transformer load current and transformer winding temperature to ensure the reliable and normal operation of the isolation transformer.

It can display the monitoring data such as current insulation voltage and transformer load rate of the medical insulation monitor in real-time, and send out an audible and visual alarm signal when the system fails, and can remotely set the alarm threshold of the insulation monitor through the alarm and display. The device is mainly installed on the information control panel in the operating room or intensive care room, so that medical staff can understand the operating status of the isolated power supply system and the type of failure when the system fails.

The insulation fault location is completed by the fault locator and the test signal generator. The high-sensitivity intervener and the high-precision signal detection circuit are mainly used to detect the signal injected into the system by the test signal generator. Accurately locate the circuit where the insulation fault is located, It is convenient for staff to maintain and overhaul.

The necessity of using medical isolated power supply

(1) Effectively ensure the normal operation of medical equipment.

(2) Prevent the current leakage current in other power supply circuits through the ground line into the operating room, IU, CCU and other special places.

(3) Medical isolation power supply reduces the ground failure of various medical equipment. Once the various medical equipment on the power supply fails the ground failure, because the ground cannot constitute a circuit, it can only produce a small capacity leakage current, which greatly protects patients from leakage current.

(4) When the insulation failure occurs in the medical equipment, due to the unscrupulous point of the power supply, when the incomplete failure fault in the load end, it will only produce a small leakage current because it cannot form a circuit. Device (such as empty) action cut off the power supply, and no sudden power outage occurred in the operating room, which is relative to ensure the continuity of the operating room power supply.

(5) The medical isolation power supply reduces the current leakage current, so it improves fire safety.

(6) In the hospital, the hospital often needs to contact the component or the ground wire in the circuit in the circuit under power-powered. Using medical isolation power supply can prevent the danger of the hospital's equipment maintenance personnel shock.

Medical isolation Power supply system configuration scheme

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

2014/35/EU

2014/30/EU

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

2014/30/EU

2014/32/EU

2014/35/EU

IEC62052-11, IEC62053-22

EN61010-1, EN61000-3

![]()

2014/30/EU

2014/32/EU

2014/35/EU

IEC62052-11, IEC62053-22

EN61010-1, EN61000-3

![]()

CE-RED, IEC, LVD, EMC

2014/30/EU

EN IEC 61000

IEC 62052

IEC 62053

IEC 61558-1

IEC 61558-2-15

IEC60364-7-710

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]