What Do Our Customers Say?

My first contact with ACREL was through Mrs. Feeling Chang. He was extremely friendly, approachable and very helpful. It will be the beginning of a long partnership between Bikoelectronics and Acrel.

Vanessa

Portugal

“ For over 4 years working with Acrel, they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. "

Arnold

Philippines

Cloud Platform for Power IoT is a synchronous integrated solution from energy meter installation to web interactive interface that can see the benefits of features with the first click mouse. Very convenient and fast. I will be with this product for a long time.

Tuan

Vietnam

Direct Access

Lead Access

PowerTag is a cutting-edge solution from Electric that monitors energy consumption and provides real-time data analytics for greater energy efficiency and savings.

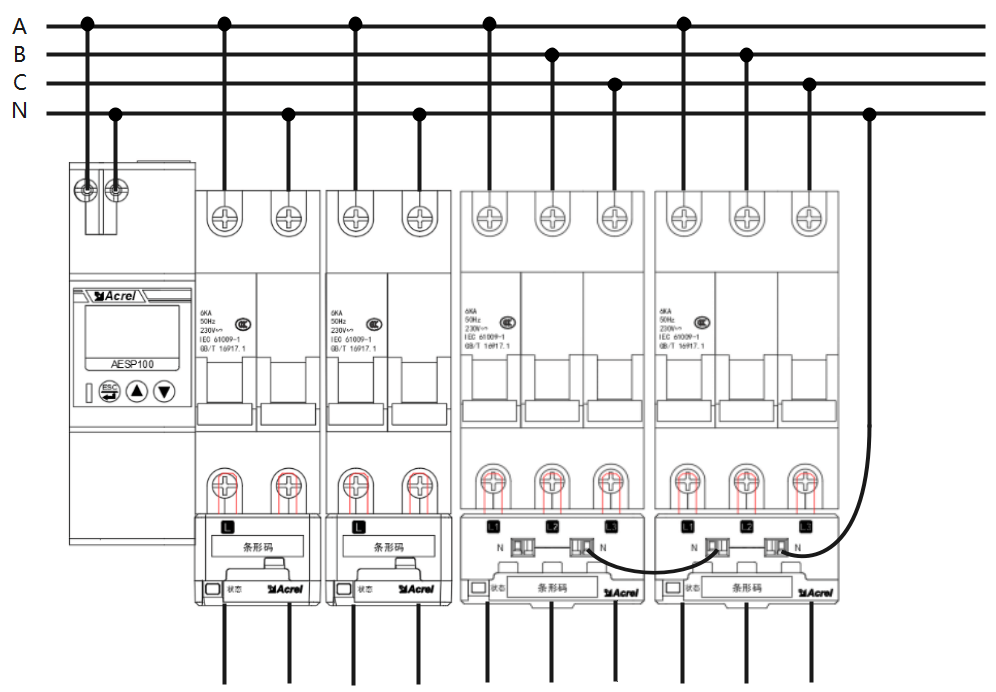

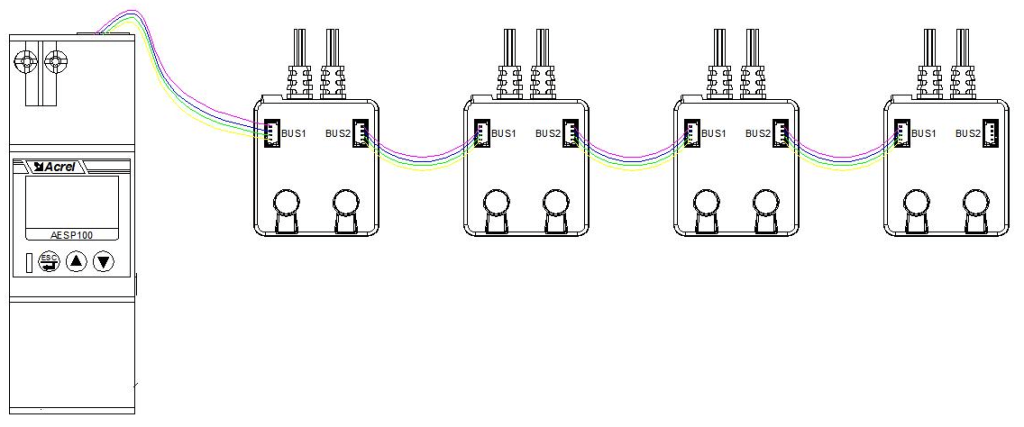

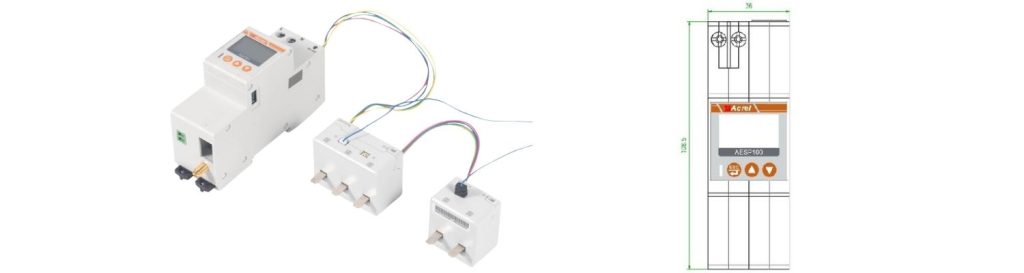

AESP100 series terminal multi-circuit intelligent power online monitoring device is applied to low-voltage terminal power distribution network in the fields of industrial, commercial, civil buildings and infrastructure in indoor buildings and similar places.

This device is used with a circuit breaker to monitor the key electrical factors of the power line in real time, such as voltage, current, power, temperature, energy consumption, etc., and has functions such as early warning and alarm, and energy metering and statistics.

This series of products is suitable for low-voltage power grid systems with single-phase, double live wire, three-phase three-wire, three-phase four-wire neutral point directly grounded (TT).

What’s the Highlight of Acrel AESP PowerTag for Circuit Monitoring?

What's the Application of Acrel AESP PowerTag for Circuit Monitoring?

PowerTag’s energy

monitoring system is an

ideal solution for

manufacturing plants,

allowing businesses to

optimize their energy

usage and reduce their

overall energy costs.

PowerTag’s real-time data

analytics help data centers

optimize their energy

usage, reduce waste, and

improve overall efficiency,

enabling businesses to

save money and reduce

their carbon footprint.

PowerTag is an ideal

solution for schools and

universities, helping them

manage their energy

consumption and reduce

energy waste, enabling

them to save on energy

costs and promote

sustainability on campus.

How does Acrel AESP PowerTag for Circuit Monitoring work?

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

What's the Function of Acrel AESP PowerTag for Circuit Monitoring?

PowerTag utilizes advanced sensing technology to track energy usage and provide real-time data analytics for facilities and plants.

PowerTag helps identify energy spikes and inefficiencies, enabling businesses to optimize their costs and reduce energy waste.

PowerTag has a quick response time and integrates with Acrel IoT architecture, providing instant alerts for any potential issues or threats to energy consumption.

The PowerTag system is centralized and scalable, with the ability to manage multiple facilities and energy data from a single location, streamlining the energy management process.

What's the Feature of Acrel AESP PowerTag for Circuit Monitoring?

PowerTag’s digital power measurement

technology provides highly accurate energy

consumption data at the circuit level.

PowerTag is compatible with a variety of

communication protocols, including Modbus, and EtherNet/IP

The PowerTag system can be easily installed

without disrupting operations or requiring

extensive wiring

What's the Benefit of Acrel AESP PowerTag for Circuit Monitoring?

Cost Savings

PowerTag’s energy management system enables

businesses to reduce their energy costs and

optimize energy usage, significantly reducing

operational costs and generating significant savings.

Sustainability

PowerTag helps businesses optimize their energy

usage, reduce waste, and increase their

sustainability, contributing to a cleaner and more

efficient future

Real-time Monitoring

PowerTag’s real-time data analytics provide

businesses with instant insight into their energy

consumption and usage, enabling them to identify

trends and optimize their energy usage in real-time.

GreaterEfficiency

PowerTag’s energy management system helps

businesses improve their overall operational

efficiency by identifying energy inefficiencies and

providing actionable insights for reducing energy

waste.

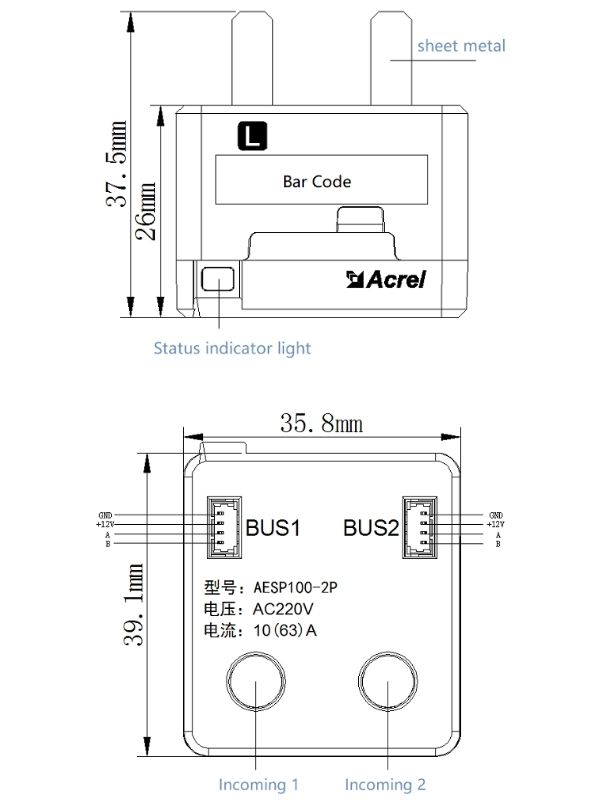

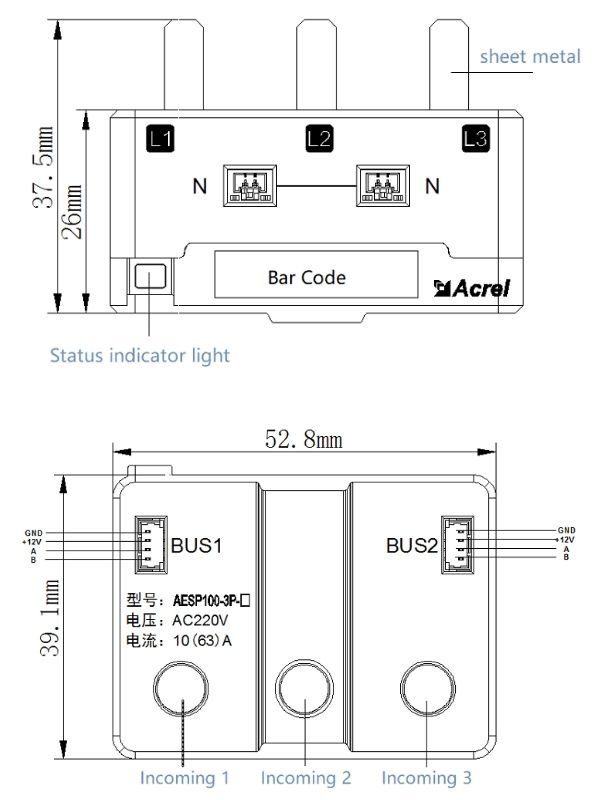

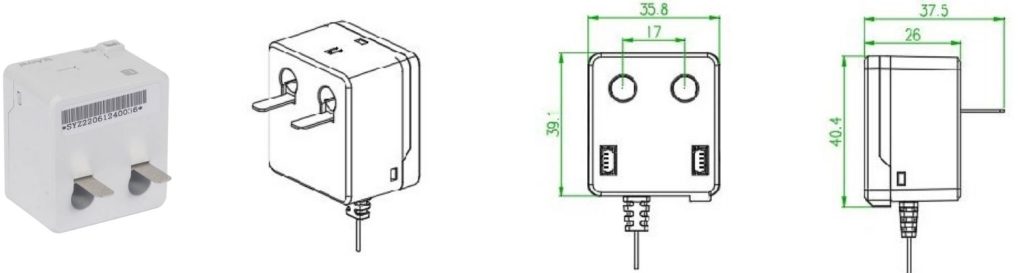

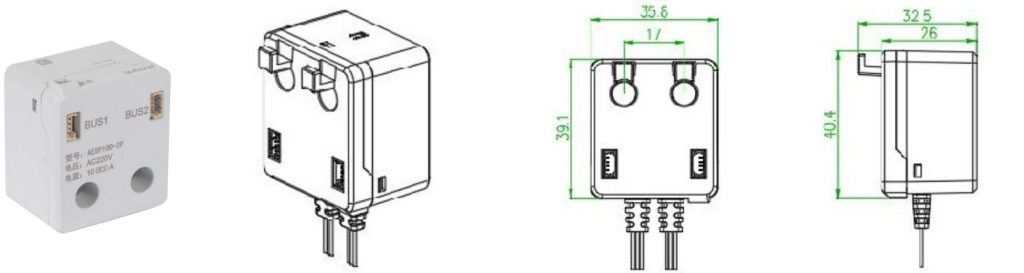

What’s the Specification of Acrel AESP PowerTag for Circuit Monitoring?

| Item | Specification | Communication | Poles | Function | |

| Powertag | AESP100-2P | RS485 MODBUS-RTU |

2 | Real-time monitoring of parameters such as voltage, current, power, electric energy and temperature; with various alarm functions such as overvoltage, undervoltage, overload, overcurrent, and overtemperature |

|

| AESP100-3P | 3 | ||||

| Item | Specification | Coomunication | Circuits | Function | |

| Uplink | Downlink | ||||

| Gateway | AESP100-M-CE | CE | RS485 MODBUS-RTU |

16 | View real-time data of each circuit: voltage, current, power, energy, temperature and leakage; View the status of each circuit: fault, alarm and opening and closing; Parameter setting and control of each loop; Event record; Din rail installation, LCD display |

| AESP100-M-4G | 4G | ||||

What’s the Parameter of Acrel AESP PowerTag Wireless Energy Sensor?

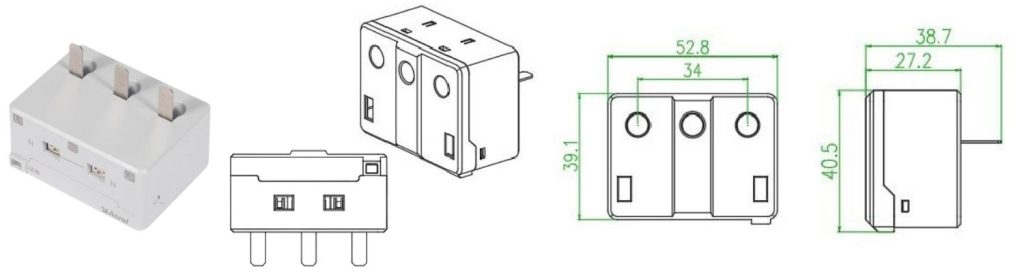

| Type | AESP100-2P | AESP100-3P | |

| Poles | 2P | 3P | |

| Aperture | 6.6mm | ||

| Number of loops | 1 or 2 single-phase circuits | 1 three-phase circuit or 3 single-phase circuits |

|

| Rated voltage | AC 220V | ||

| Rated current | 10(63)A | ||

| Alarm

Function |

Over-current | Default 100% rated current warning, 110% rated current warning, adjustable threshold |

|

| Over-load | Default 100% rated power warning, 110% rated power alarm, adjustable threshold |

||

| Over-voltage | Default 110% rated voltage warning, 120% rated voltagewarning, adjustable threshold |

||

| Under-voltage | Default 90% rated voltage warning, 80% rated voltage alarm, adjustable threshold |

||

| Overt-emperature | Default 80℃ early warning,100℃ alarm, adjustable threshold | ||

| Protection class | IP30 | ||

| Altitude requirements | 2000m | ||

| ambient temperature | -10℃~55℃, 24h average temperature not higher than 40℃ | ||

| Environmental requirements |

No explosion hazard, no conductive dust, no enough to corrode metal and damage insulation,no significant vibration |

||

| Relative humidity | At +40°C, the relative humidity of the air is 50%, and it can have a higher relative humidity at lower temperatures |

||

| Storage temperature | -20℃-70℃ | ||

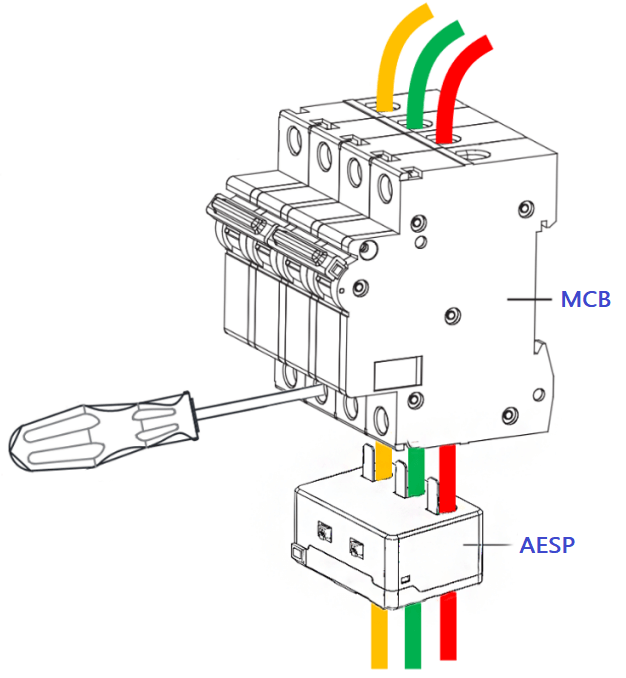

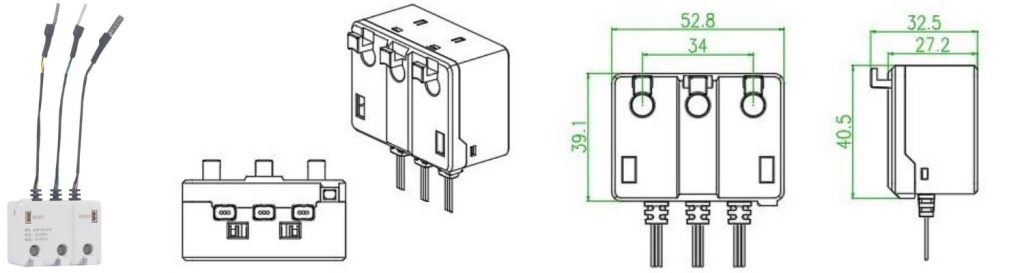

| Installation method | Direct installation or lead wire installation with circuit breaker | ||

What’s the Parameter of Acrel AESP Power Tag Gateway?

| Type | AESP100-M-4G | AESP100-M-CE |

| Power supply | AC 220V | |

| Power consumption | ≤30W | |

| Communication | 4G | Ethernet |

| Display | LCD display | |

| Record | Alarm, fault and action records up to 20 records each | |

| Protocol | Modbus、MQTT | |

| Altitude requirements | 2000m | |

| Ambient temperature | -10℃-45℃,24h average temperature not higher than 35℃ |

|

| Environmental requirements | No explosion hazard, no conductive dust, no enough to corrode metal and damage insulation, no significant vibration |

|

| Relative humidity | At +40°C, the relative humidity of the air is 50%, and it can have a higher relative humidity at lower temperatures |

|

| Storage temperature | -20℃-70℃ | |

| Protection class | IP20 | |

| Installation method | Standard 35mm Din rail installation | |

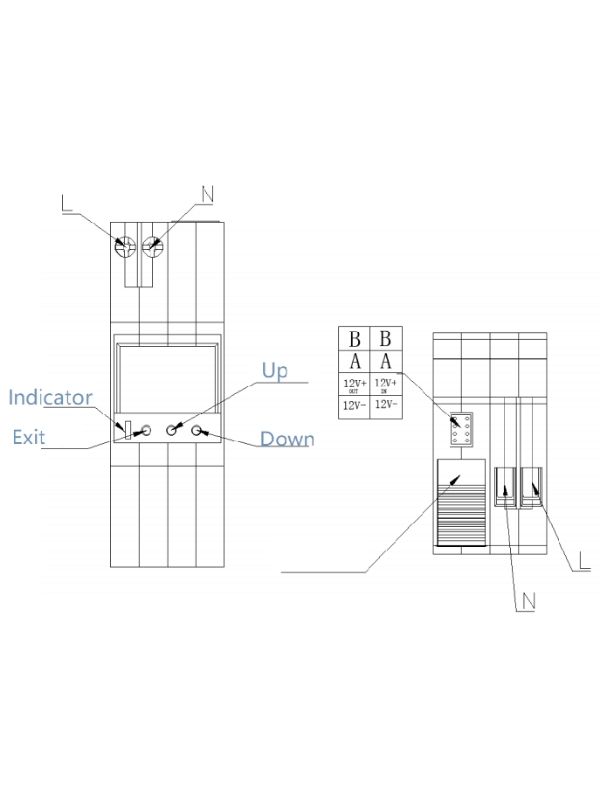

The Terminal of Acrel AESP PowerTag Wireless Energy Sensor?

How to Wire Acrel AESP PowerTag Wireless Energy Sensor?

What’s the Dimension of Acrel AESP PowerTag Wireless Energy Sensor?

Got a Question? Get your Answer

We have our own Factory and R&D Center

Rich product series: Cloud Platform, Gateway, Protection Device, Power Meter, Transformer

CNAS, ISO14001, ISO27001, ISO9001

CE, IEC, MID, UL, EAC, ROHS, REACH

Competitive Price with High Quality

2 Years

Purchasing according to your needs, no MOQ limit

Sample takes 3 days; Bulk purchase takes 1 month

2014/30/EU

EN IEC 61000

IEC 62052

IEC 62053

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

2014/30/EU

EN IEC 61000

2014/35/EU

EN 61010

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]