The substation operation and maintenance cloud platform can be regarded as the network application extension of the power monitoring system.

The operation and maintenance cloud platform of the substation is through the Internet, and the power operation and maintenance personnel can understand the operation of the power distribution system of the factory anytime and anywhere through their mobile phones.

It can be unattended or with few people on duty, and at the same time, it can monitor energy consumption, leakage, abnormal heating of cables, etc.

And can dispatch tasks through the APP, close the loop elimination process, and eliminate hidden dangers in time.

What's the Difficulty of Factory Substation Operation and Maintenance?

What's the Highlight of Factory Substation Operation and Maintenance?

How to Configure the Factory Substation Operation and Maintenance Cloud Platform?

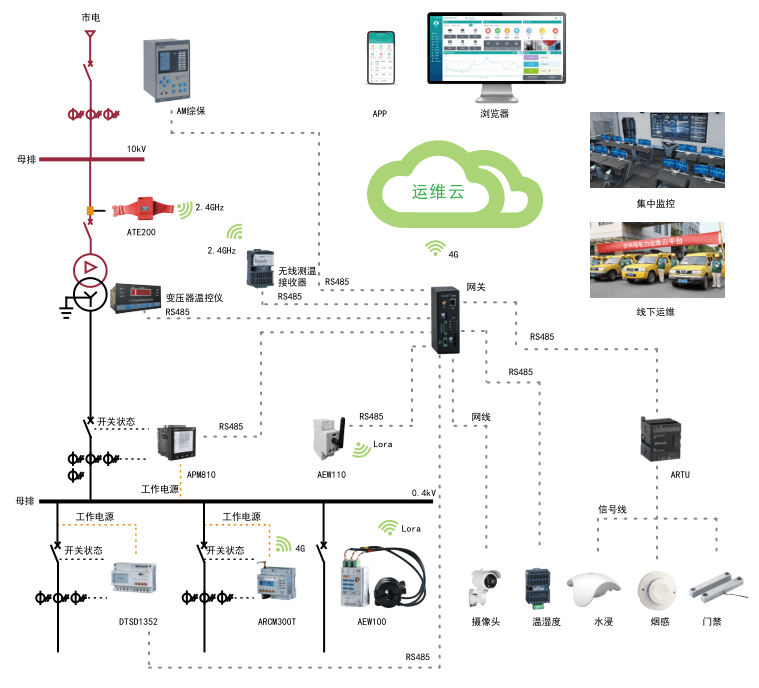

AcrelCloud-1000 power operation and maintenance cloud platform adopts multi-functional power sensor, wireless communication, edge computing gateway, and big data analysis technology.

Collect on-site data through the intelligent gateway and store it locally, and then push the data to the cloud platform regularly.

The data collected by the platform includes the electrical parameters of the substation circuit and the transformer temperature, ambient temperature and humidity, water immersion, smoke, video, access control and other information. If an abnormality occurs, an alarm signal will be sent through SMS and APP within 10S.

The platform sends the operation and maintenance tasks to the mobile phone of the designated personnel through the mobile phone APP and tracks the operation and maintenance execution process through GPS to close the loop, improve the operation and maintenance efficiency, and immediately find the operation defects and eliminate them.

What's the Solution for Factory Substation Operation and Maintenance?

The software adopts B/S architecture.

and the system data and alarm information can be viewed through the computer WEB terminal, tablet, or mobile APP.

What's the Function of Factory Substation Operation and Maintenance Cloud Platform?

The substation status includes overview, operation status, event record of the day, hourly electricity consumption curve of the day, and electricity consumption overview.

Support large-screen display of user operation and maintenance substation overview, environmental monitoring, real-time voltage, real-time load, real-time electricity, distribution diagram, etc.

The system collects the UPS input, output, and bypass electrical parameters, monitors the UPS temperature, battery voltage, remaining time under the current load, etc., sends an alarm signal in time when an abnormality is detected, and grades it according to the degree of urgency.

The power data displays the power data and curve of the selected circuit of the selected substation. The curve displays the large, small and average values within the statistical period, and supports exporting charts.

Display the harmonic data of a certain circuit of the selected substation, and you can view the harmonic data of a certain circuit by selecting the harmonic type and harmonic quantity.

The energy consumption report shows the energy consumption data of each circuit, including daily, monthly, and annual reports. The daily report shows the time-sharing energy consumption, the monthly report shows the daily energy consumption, and the annual report shows the monthly energy consumption.

The event record is convenient for operation and maintenance personnel to view and analyze the records of equipment such as circuit breaker closing and opening, door opening and closing, current and voltage over-limit alarm, fault alarm, SMS log, platform operation log, etc.

Display the leakage current, cable temperature and alarm status of the selected substation.

The operating environment includes environmental monitoring, video monitoring, ambient temperature and humidity, instrument communication status, gateway communication status, video monitoring, video equipment status, etc.

Equipment management includes equipment definition, equipment file and equipment report, and the equipment of the substation is maintained and processed in the equipment file.

Operation and maintenance management includes three parts: task management, inspection records, and defect records. Among them, task management can complete task creation, release, and task completion query; inspection records are the execution status and execution details of inspection tasks, and defect records are eliminated. Missing task creation, release, and completion status query.

The user report page is mainly used to automatically summarize the operation data of the selected substation for one month, perform statistical analysis on the transformer load, power consumption of the distribution circuit, power factor, alarm events, etc., and list them in the cycle. Various defects were found during the inspection and their handling.

2014/35/EU

2014/30/EU

2014/30/EU

EN IEC 61000

IEC 62052

IEC 62053

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

2014/30/EU

EN IEC 61000

2014/35/EU

EN IEC 61000

EN61010

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]