The power monitoring system realizes the functions of monitoring, measuring, recording, and alarming transformers, diesel generators, circuit breakers, and other important equipment.

And communicate with protective equipment and remote control centers and other equipment, Real-time grasp of the operation status of the power supply system and possible hidden dangers, quick troubleshooting, and improve the reliability of the power supply in the factory.

What's the Difficulty of Monitoring Factory Power?

What's the Highlight of Factory Power Monitoring Solution?

How to Configure the Factory Power Monitoring Solution?

The power monitoring system is mainly aimed at switching stations and 10/0.4kV substations.

The high-voltage circuit is equipped with a microcomputer protection device and multi-function instrument to protect and monitor,

Configure multi-function metering instrument for 0.4kV outgoing line,

It is used to measure and control the electrical parameters and energy consumption of the outgoing circuit.

At the same time, monitor the status of important plant equipment such as diesel generators, reactive power compensation devices, active filter devices, UPS, and isolated power systems.

What's the Solution for Monitoring Factory Power?

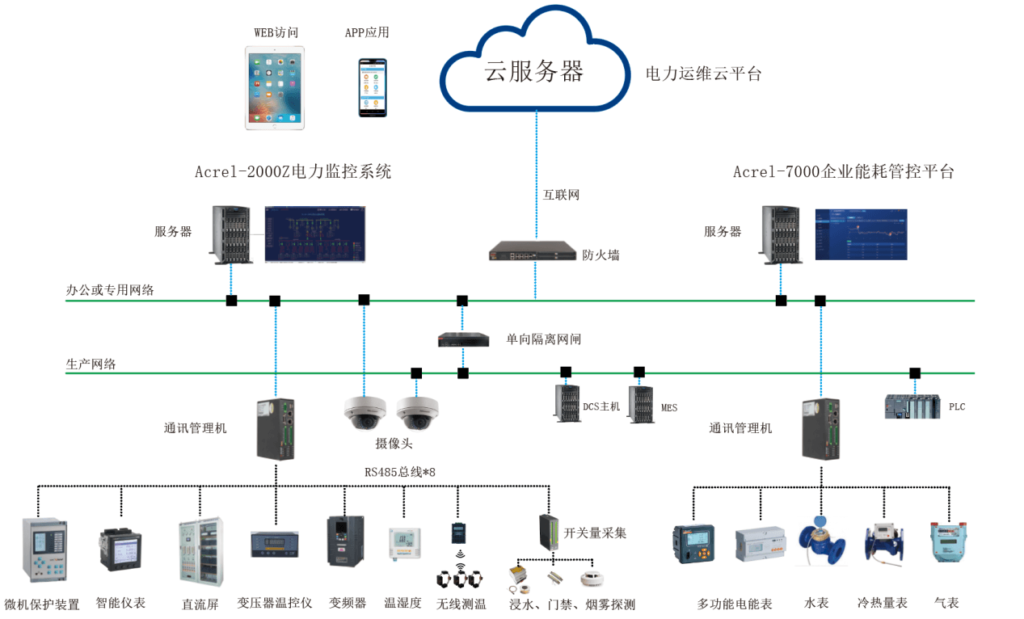

The system adopts a distributed structure,

Microcomputer protection devices, multi-function instruments, transformer thermostats, DC panels, diesel generator control panels, and other equipment are connected to the intelligent gateway through the RS485 bus or Ethernet.

After protocol conversion and data processing, it is uploaded to the power monitoring system.

Realize telemetry, remote signaling, remote control, abnormal alarm, and other functions.

What's the Function of Factory Power Monitoring Solution?

Visually display the operating status of the distribution line in the form of a primary distribution diagram, monitor the electrical parameter information of each circuit in real-time, and dynamically monitor the closing and opening status of each distribution circuit breaker, diesel generator status, UPS status, battery information, etc.

In the primary distribution diagram, you can directly view the detailed electrical parameters of the circuit, and you can view the 24-hour phase current trend curve.

The system collects the UPS input, output, and bypass electrical parameters, monitors the UPS temperature, battery voltage, remaining time under the current load, etc., sends an alarm signal in time when an abnormality is detected, and grades it according to the degree of urgency.

The system can display the electrical parameters of the incoming line and feeder loop in the precision power distribution cabinet, and perform alarm settings and classification for the data. The data is taken from the measurement module of the precision power distribution cabinet.

The power monitoring system has a real-time voice alarm function

It stores and manages remote signal displacement, protection action, accident trip, electrical parameters, etc., which is convenient for users to trace the history of system events and alarms, query statistics, and analyze accidents.

The system has the function of regular meter reading, and summary statistics, and users can freely inquire about the power consumption of each distribution node in any time period since the normal operation of the system.

User rights management can prevent unauthorized operations and can define login names, passwords, and operating rights of users at different levels, providing reliable security for system operation, maintenance, and management.

The power monitoring system can remotely control the equipment in the whole power distribution system.

Complete display of the entire system network structure; online diagnosis of equipment communication status, automatic display of faulty equipment or components and their fault locations on the interface when network abnormalities occur.

2014/35/EU

2014/30/EU

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

2014/30/EU

EN IEC 61000

IEC 62052

IEC 62053

Standard Lead Time:

Standard Lead Time:

Sample: 2 days

Bulk: 1 month

2014/30/EU

EN IEC 61000

2014/35/EU

EN 61010

2014/30/EU

EN IEC 61000

2014/35/EU

EN IEC 61000

EN61010

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]

Kindly Fill out the Form below and tell us more about your Requirements,

We would like to provide Suitable Solution for You.

or Send us Email directly, [email protected]